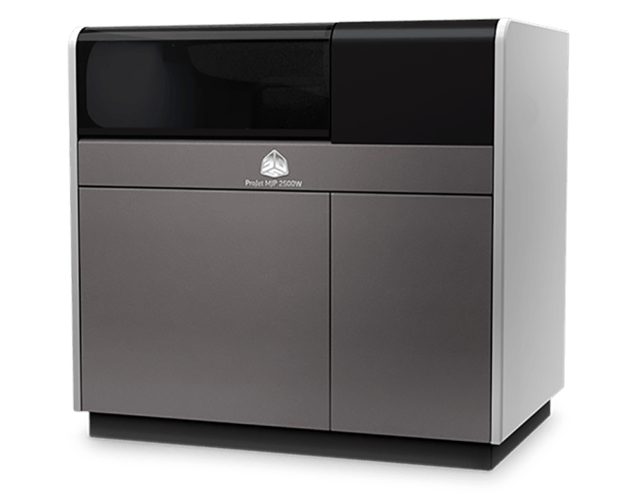

3D Systems Projet 2500W

OUR RANGE OF MARKET-LEADING PRINTERS

Casting reliability

The ProJet® MJP 2500W 3D prints in VisiJet® M2 CAST 100% wax material to deliver durable, high-quality jewelry patterns for reliable performance and results throughout existing lost-wax casting processes and equipment.

VisiJet M2 CAST melts like standard casting waxes, with negligible ash content for defect-free castings. It is durable for handling and casting fine features, and its high contrast deep purple color allows for easy fine details visualization.

High Productivity

Featuring fast wax patterns production, at up to 10x faster print speed than similar class solutions, and even faster workflow with single-lane builds, the ProJet MJP 2500W improves the casting room efficiency. With a 3.7x larger build volume capability than similar class printers and 24/7 operation, the high productivity of this affordable printer means fast amortization and high return on investment.

Streamline your file-to-pattern workflow with the advanced 3D Sprint® software capabilities, fast and versatile MJP print speeds and batch support removal to deliver high quality, ready-to-cast jewelry patterns.

High Resolution Patterns

Consistently print true-to-CAD and fine feature definition jewelry patterns with exact, razor-sharp edges and extreme crisp details. Smooth surface and sidewall quality mean less expensive handwork and a faster pattern-to-finished piece workflow. These highly accurate, fine wax patterns are directly printed, without the time, costs and geometric limitations of tooling.